Custom Plastic Shims

Custom plastic shims with higher quality, lower costs, and one-week shipments on most orders. Drop-shipped to your site.

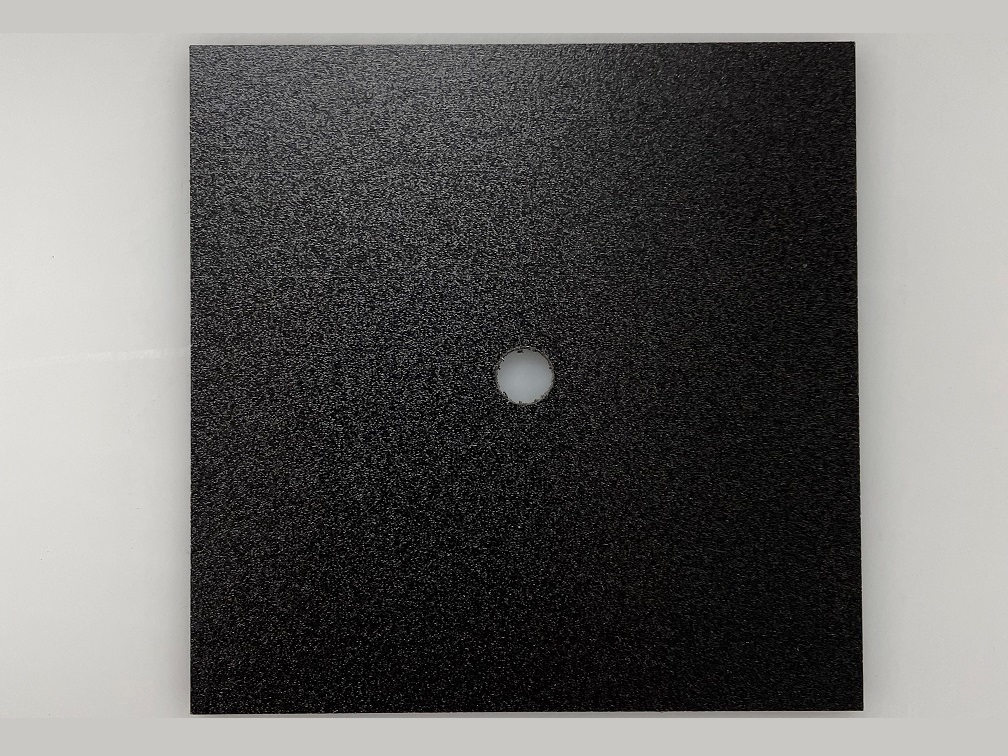

Action Plastics is your source for custom plastic shims. HIPS, ABS, HDPE. 1/16″, 1/18″, 14″, and 2″. Flat, key slot, center hole, and horseshoe-shaped.

Custom plastic shims with higher quality, lower costs, and one-week shipments on most orders. Drop-shipped to your site.

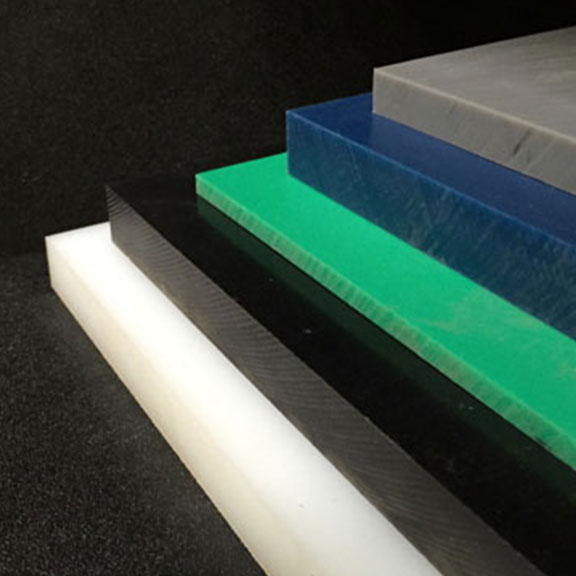

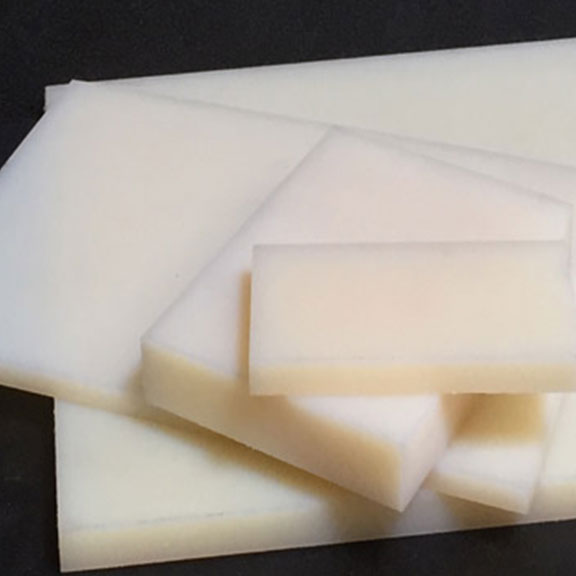

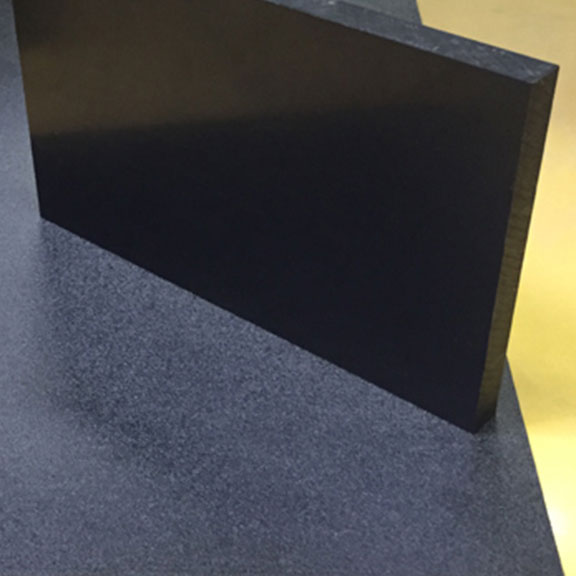

Choose a strong, lightweight, and environmentally resistant plastic. You can even choose UV-stabilized materials. Most custom plastic shims are made of ABS or HIPS. Normally, ABS sheets come in thicknesses of 1/2" or 3/8". HDPE sheets are available in thicker sizes and cost less than ABS or HIPS when you need a thicker material.

The most common thicknesses for plastic shims are 1/16, 1/8, and 1/4. Although those are the most common, our custom capabilities can meet your project requirements. Common shim dimensions range from as small as 2" x 2" to as large as 10" x 10". Smaller and larger shims are available upon request. Because our plastic shims are machined instead of molded, you won't have to pay for a different tool every time you need a different-sized shim.

Use custom plastic shims with any type of masonry, including cinder blocks and bricks. They're a lot better than those old-fashioned wooden shims in normal construction, whether it's masonry or bricks and sticks. These custom plastic shims are a great choice for doors, windows, retaining walls, and many other building and construction projects.

Just set them on the block, or slide and lock them into place. Custom plastic shims with a hole or slot fit over a bolt or threaded rod so that you can screw down and anchor them in place. No matter how you place them, custom shims from Action Plastics are build to take heavy loads.

Strong, lightweight and designed to fit around bolts and anchors.

Ideal for spacing, aligning, and solving leveling problems.

Shaped to snap in place with a restricted slot to keep them for sliding off.

Built to handle heavy loads., often permanently, and with slip-resistance.

| Thickness | Sheet Length | Sheet Width | Shim Length | Shim Width | Pcs. Per Sht. |

|---|---|---|---|---|---|

| 1/16 – 3/4 | 96 | 48 | 2 | 2 | 968 |

| 1/16 – 3/4 | 96 | 48 | 3 | 2.5 | 540 |

| 1/16 – 3/4 | 96 | 48 | 4 | 2.75 | 368 |

| 1/16 – 3/4 | 96 | 48 | 5 | 3 | 270 |

| 1/6 – 3/4 | 96 | 48 | 6 | 3.125 | 210 |

| 1/16 – 3/4 | 96 | 48 | 7 | 3.25 | 182 |

| 1/16 – 3/4 | 96 | 48 | 8 | 3.50 | 143 |

| Thickness | Sheet Length | Sheet Width | Shim Length | Shim Width | Pcs. Per Sht. |

|---|---|---|---|---|---|

| 1/16 – 3/4 | 120 | 60 | 2 | 2 | 1485 |

| 1/16 – 3/4 | 120 | 60 | 3 | 2.5 | 836 |

| 1/16 – 3/4 | 120 | 60 | 4 | 2.75 | 580 |

| 1/16 – 3/4 | 120 | 60 | 5 | 3.00 | 437 |

| 1/16 – 3/4 | 120 | 60 | 6 | 3.125 | 342 |

| 1/16 – 3/4 | 120 | 60 | 7 | 3.250 | 272 |

| 1/16 – 3/4 | 120 | 60 | 8 | 3.500 | 224 |

| Thickness | Sheet Length | Sheet Width | Shim Length | Shim Width | Pcs. Per Sht. |

|---|---|---|---|---|---|

| 1/16 – 3/4 | 120 | 48 | 2 | 2 | 1210 |

| 1/16 – 3/4 | 120 | 48 | 3 | 2.5 | 684 |

| 1/16 – 3/4 | 120 | 48 | 4 | 2.75 | 464 |

| 1/16 – 3/4 | 120 | 48 | 5 | 3.00 | 345 |

| 1/16 – 3/4 | 120 | 48 | 6 | 3.125 | 266 |

| 1/16 – 3/4 | 120 | 48 | 7 | 3.25 | 224 |

| 1/16 – 3/4 | 120 | 48 | 8 | 3.5 | 183 |

| Thickness | Sheet Length | Sheet Width | Shim Length | Shim Width | Slot Length | Pcs. Per Sheet |

|---|---|---|---|---|---|---|

| 1/16 – 3/4 | 96 | 48 | 4.5 | 2 | 4 | 288 |

| 1/16 – 3/4 | 96 | 48 | 4.5 | 2.5 | 4 | 234 |

| 1/16 x 3/4 | 96 | 48 | 4.5 | 3 | 4 | 216 |

| 1/16 – 3/4 | 96 | 48 | 4.5 | 3.5 | 4 | 170 |

| 1/16 – 3/4 | 96 | 48 | 4.5 | 4 | 4 | 162 |

| 1/16 – 3/4 | 96 | 48 | 4.5 | 4.5 | 4 | 128 |

| 1/16 – 3/4 | 96 | 48 | 5.0 | 5.0 | 4 | 105 |

| Thickness | Sheet Length | Sheet Width | Shim Length | Shim Width | Number of Holes | Pcs. Per Sheet |

|---|---|---|---|---|---|---|

| 1/16 – 3/4 | 96 | 48 | 4.5 | 2 | 1 | 288 |

| 1/16 – 3/4 | 96 | 48 | 4.5 | 2.5 | 1 | 234 |

| 1/16 – 3/4 | 96 | 48 | 4.5 | 3 | 2 | 216 |

| 1/16 – 3/4 | 96 | 48 | 4.5 | 3.5 | 2 | 170 |

| 1/16 – 3/4 | 96 | 48 | 4.5 | 4.0 | 2 | 162 |

| 1/16 – 3/4 | 96 | 48 | 4.5 | 4.5 | 3 | 128 |

| 1/16 – 3/4 | 96 | 48 | 4.5 | 5 | 3 | 105 |

Action Plastics uses materials from ISO 9001:2015 certified mills